Enabling smarter mining through the intelligent application of IMS planning tools

Currently RF surveys are conducted by driving light vehicles around site to identify trouble areas.

In order to accurately analyse wireless coverage, miners have previously conducted drive testing of the in-pit communications environment; with IMS and OTSC support this is unnecessary. Customers can see instant data and lower the HSE risks by significantly reducing LV-HV interaction and exposure to mine operations.

Traditionally, to gather the data required to understand how well your wireless coverage patterns were being received, it would require a small team with expensive equipment to enter the pit, drive the routes and continuously capture RF data in order to validate wireless coverage, upon the team’s return to the office, the data was post processed and analysed.

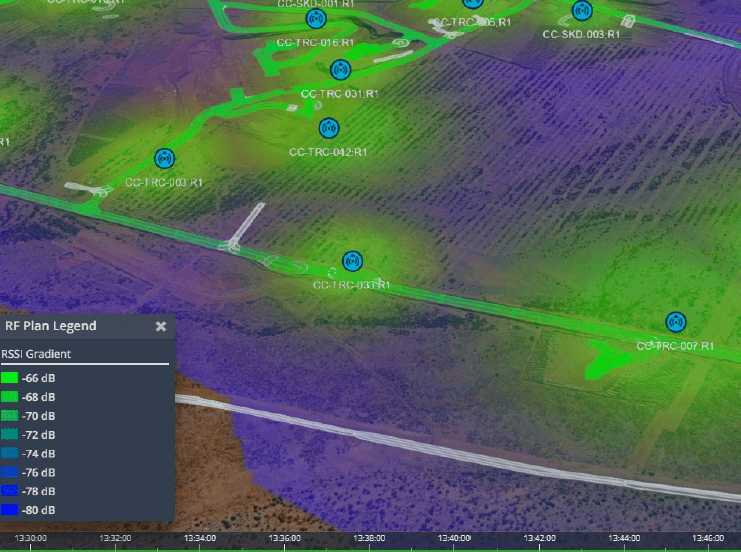

Utilising IMS’ heatmapping and RF planning tools we can project a live heatmap and RF propagation model onto a 3D map and completely remove the need to deploy personnel into the active mining area.

IMS is also equipped with an RF path profiling toolset that enables the feasibility of point-to-point links to be assessed from the desktop without the need to conduct a site survey. This further reduces the time in the pit and exposure of personnel to the mine environment.